Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

80% of production can be finished at factory

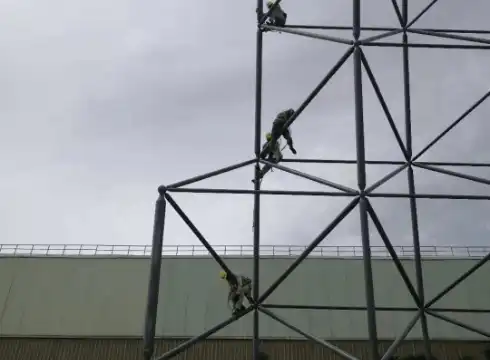

Easy and fast installation

Cost-effective

High security

Roof and side enclosures can be installed on the ground and lifted successfully once

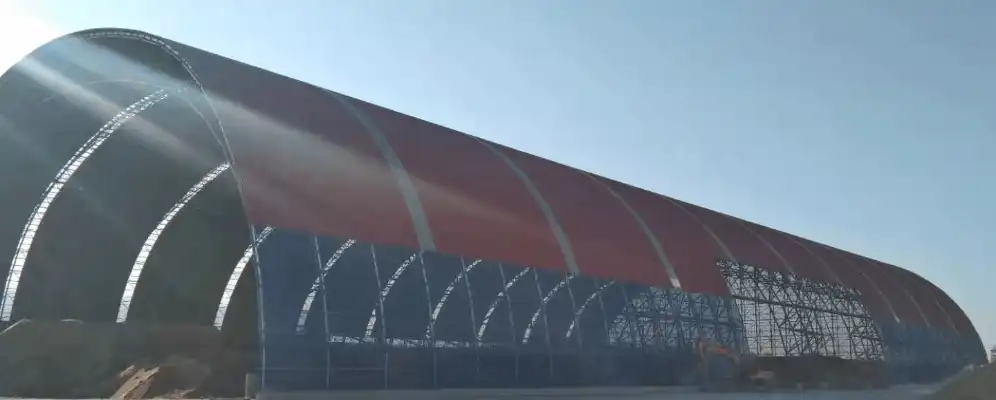

The main body of the steel structure space frame shed: a 180-meter-long, 100-meter-span bottom-chord support space frame shed with a maximum clear height of about 33 meters, a planned stacking height of 22 meters, and a top width of 16 meters. The top of the stack from the shed roof at the lowest point is less than 8 meters.

The gable on one side is closed with a dust suppression net, and the gable on the other side is completely open. Use wind and dust suppression nets within 10 meters of the side elevation of the space frame. Two gates are reserved for the feeding port, with a width of not less than 17 meters and a height of not less than 11 meters. 14-point anti-collision piers should be set inside and outside the gate and at necessary positions. The roof is equipped with a ventilation skylight with a length of 60m.

Environmental protection rain shelter for the feeding port: 68 meters long, 46 meters wide which approximately rectangular structure, with flat-top space frame structure, 12 meters high, and an area of about 2550 square meters. The interior requires a large span and no supporting columns.

The axial span of the support of the reticulated shell in the stockyard is 100m, the elevation of the spherical center of the support is +1.00m, and the elevation of the space frame is 35.519m, which belongs to the large-span reticulated shell, and the manufacturing process of the steel space frame is complicated.