Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

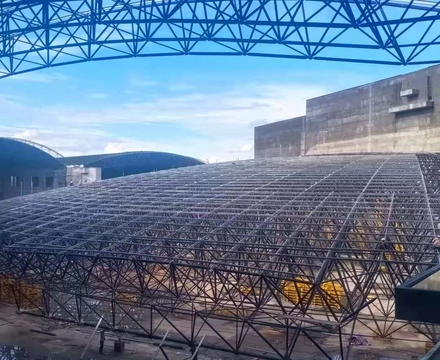

Space frame construction is a process of machining steel or other metal materials into space frames with specific shapes and sizes. Space frames have a wide range of applications in the fields of construction, bridges, and industrial equipment. The advantages of space frame structures include lightweight structure, short construction period, and adaptability. However, it also faces challenges, such as high machining accuracy requirements, high technical requirements, and high cost. Below SAFS Steel Structure Engineering Co., Ltd. will introduce the advantages and challenges of space frame structure in detail.

Structural Lightweight: Space frame structures are constructed from thin-walled steel tubes, steel plates, or other metal materials, and the overall weight is relatively light. This makes space frame structures the preferred choice for large-span projects, such as convention centers, stadiums, and airport buildings. Compared with traditional concrete structures, space frame structures are lighter in weight, reducing the pressure of the building’s dead weight on the foundation, as well as reducing the consumption of labor and mechanical equipment during construction.

Short construction cycle: Since space frame structures are mainly composed of prefabricated components, they can be processed and manufactured in the factory and then transported to the site for installation. The processing and manufacturing process of the prefabricated components can be carried out in parallel with the on-site construction, greatly reducing the construction cycle of the entire project. This is very advantageous for projects that need to be built quickly.

Adaptable: space frame structures can be customized according to different design requirements and usage environments. By adjusting the size, shape and material of the components, it can meet the specific requirements of different buildings or equipment. Meanwhile, space frame structures can be easily disassembled and reassembled, which is conducive to later maintenance, upgrading and remodeling. This adaptability advantage makes space frame structure widely used in different application scenarios.

High level of visualization: Space frame structures usually have an open appearance and the interior of the building or equipment can be seen through the grid structure. This provides better visualization and viewing for places such as scientific research, exhibition halls, and gymnasiums. Additionally, space frame structures can make full use of natural light and wind power, improving the environmental comfort and energy efficiency of the building.

High machining accuracy requirements: Space frame structures usually require high precision machining and fabrication to ensure the stability and safety of the structure. Especially in large buildings and bridges and other projects, the machining accuracy of steel tubes and nodes of space frame structures is required to be higher. Therefore, it is necessary to have fine processing equipment and technology to ensure the precision and quality of the components.

Higher technical requirements: Space frame structures require a certain level of skill and experience to cope with a wide range of complex structural and design requirements. For example, processes such as cutting, bending and welding of steel pipes require a high degree of technical proficiency and specialized knowledge. Structural analysis, design and testing capabilities are also required to ensure the safety and stability of space frame structures.

Higher costs: Space frame structures have higher material costs compared to traditional concrete structures. Steel and other metal materials are more expensive, and the processing and manufacturing process requires a certain amount of energy and human resources. In addition, the processing, installation and construction processes of space frame structures are relatively complex and require more investment in manpower and mechanical equipment, so the overall cost will be higher.

Anti-corrosion and difficult maintenance: Space frame structures are usually in open-air environments and are susceptible to oxidation and corrosion. Therefore, anti-corrosion measures for space frame structures are very important, such as coating treatment and anti-rust treatment. In addition, because space frame structures are hollow inside, the hidden parts are difficult to maintain, and regular inspection and maintenance are needed to ensure the safety and reliability of the structure.

In summary, space frame structure has advantages such as lightweight structure, short construction period, strong adaptability and high visualization, but it also faces challenges such as high machining precision requirements, high technical requirements, high cost and high difficulty in anticorrosion and maintenance. With the continuous progress of science and technology and the improvement of technology, these challenges can be solved to a certain extent, so that the space frame structure can play a greater advantage and role in more fields.