Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

1. Characteristics of BIM technology

BIM technology is a new technology with a wide range of applications, which has an important impact on construction work. BIM is a building information model. In the actual application process, the real parameter information of the building is mainly input into it, and then the system will simulate and model it to provide an effective reference for the subsequent construction work. The characteristics of BIM technology are mainly reflected in the following two points:

(I) The information has strong authenticity and completeness

In the process of building information modeling, BIM technology can grasp more information to a certain extent, and the authenticity and integrity of the information will also be guaranteed. This can ensure the rationality of staff decision-making, improve information utilization, and lay a good foundation for future work.

(II) Strong visualization and simulation characteristics

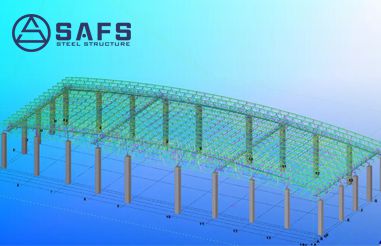

In the application of BIM technology, the entire construction process and building structure will be more intuitively presented to the staff through images or models, so that the staff can have a correct understanding of the actual construction situation, clarify the construction points and construction direction, etc.

2. Prefabricated buildings

In recent years, the concept of green energy saving has been widely used in buildings. From the perspective of my country’s current construction industry, the consumption of building materials and incomplete construction will not only bring certain economic losses to construction companies and the government, but also have an impact on the natural environment. In this context, prefabricated construction should be strengthened. The construction principle of prefabricated buildings is very similar to that of building blocks. In fact, after the main structure design of the construction project is completed, the main body of the construction is matched one by one. Each node and auxiliary unit is usually a cost material or a semi-finished material. Its main construction features are convenient construction, low investment, and guaranteed building quality and safety. Therefore, this construction method has been adopted in many projects and achieved good construction results. The application of BIM technology in the construction of prefabricated buildings is mainly reflected in the following points: First, it provides guarantees for the full-cycle management of prefabricated buildings and promptly discovers problems in construction. In response to these problems, corresponding preventive measures and solutions are proposed. Using BIM technology to simulate the construction process and make reasonable evaluations is of great significance to the comprehensive upgrading of construction. Second, it improves the construction quality and efficiency of prefabricated buildings. In the application process of BIM technology, the prefabricated building can be designed as a whole in the shortest time, and then a scientific and reasonable construction plan can be formulated based on the actual situation. In this way, the comprehensive upgrade and optimization of component transportation and on-site scheduling can be achieved, and the construction work can be carried out in an orderly manner.

3. Application of BIM technology in prefabricated buildings

(I) Application in the design stage

In actual assembly projects, BIM technology can be applied to the design stage. There are mainly the following points: First, in the assembly construction project, the development of various tasks should be planned and planned in advance. Whether in production, design or construction, prefabricated components should be scientifically and reasonably designed, processed and assembled to promote the design and production of prefabricated components, and gradually develop in the direction of standardization and standardization.

In this process, BIM technology should be reasonably used, and three-dimensional numbers should be used as a means of expression. At the same time, BIM technology should be used to make corresponding building components, such as HVAC warehouses, water supply and drainage household warehouses, etc. Secondly, BIM technology should not only be applied to component design, but also combined with corresponding parameters. The main purpose of BIM technology is to achieve the separation of components, such as vertical components, horizontal components, stress-free components, etc. In the design and production process of prefabricated components, attention should be paid to the hoisting of wall beams and columns, and the processing and transportation of components should be considered. Carefully analyze the reserved hole work, embedded parts work and opening work of the components in the installation. Third, BIM technology can also be used for collision detection. In actual collision detection, BIM technology can make reasonable use of different professional models to find problems in the design, so as to communicate and communicate with designers in time to better solve problems in the design. For example, in the modeling of electromechanical pipelines, the quality of the pipelines should be checked in time to avoid errors and leakage. This can avoid design changes to a certain extent, thereby ensuring the quality of the design. There are two main ways to apply BIM technology to collision detection: one is to directly modify the parameters of the collision point. This method is intuitive, targeted and efficient. However, this method is not suitable for multiple collision detection; secondly, the parameter modification in the BIM family library can realize the modification of the component family, so that the component family can be updated and improved in time. In the actual collision point detection, effective detection methods should be adopted in combination with actual conditions to improve the detection quality and detection efficiency. Fourth, the chip that supports wireless reading and writing is embedded in the production of assembled building components, and the component number, location, size, reinforcement, date, quality, production workshop and other related information are written into the chip, and then the mold, spray release agent, tie steel cage, fix embedded parts, concrete cloth, vibration table vibration, maintenance demoulding can be installed. On this basis, the quality inspector uses the handheld terminal to read the chip parameters to ensure the consistency of the component entity and the parameters, and judge whether the production quality meets the requirements; after confirmation, the results are written into the chip and stored in the warehouse, and the warehouse manager verifies and saves them; the ID card should be checked before loading and the transportation information should be entered; after arriving at the construction site, the ID card should be scanned and verified, and the on-site inspection information should be entered; and the information in the installation of related components should be checked again. Through the above process and method, the BIM technology is introduced into the embedded chip, which can meet the traceability of the entire process of prefabricated component installation and construction, and achieve the purpose of improving construction quality, work efficiency and cost control.

(II) Application in the on-site installation and construction stage

BIM technology can be applied not only in the architectural design stage, but also in the on-site installation and construction stage. In the actual construction work, the following issues should be noted: First, based on BIM technology, the simulation of key processes during construction can be realized to select the best process solution. Taking the construction technology of prefabricated building compartment slurry as an example, the general process requires the placement of gaskets with a thickness of 20.0cm to ensure the thickness and uniformity of the slurry, while avoiding the gasket itself from affecting the fluidity of the slurry. Second, in the application of BIM technology, different facilities on site and model construction work can be carried out in an orderly manner. In the layout of the site plan, it is necessary to organically combine the layout points and layout technology, so that the development of the design work can be carried out safely and orderly. There must be an area that meets the construction standards at the construction site. Whether it is a logistics channel or a pedestrian channel, it must be designed in advance to avoid blockage. The construction site also requires staff to make scientific and reasonable plans, so BIM technology can be used to simulate the actual construction situation on site. In this process, it is necessary to strengthen the application of the visualization advantages of BIM technology, simulate the electromechanical pipeline conditions in the basement, and then ensure the scientificity and rationality of the electromechanical selection based on the simulation results, and ensure that the equipment parameters meet the relevant regulations. Third, apply BIM technology to the simulation of large-scale equipment installation and disassembly process, so that the entire construction process can be simulated in advance, problems in construction can be discovered as early as possible, and problems should be analyzed and discussed in a timely manner, and preventive measures and solutions should be given.