Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Aluminum-magnesium-manganese plates are widely used in general industrial, agricultural, commercial, and service buildings, such as office buildings, villas, warehouses, sports venues, entertainment, tourism buildings, and low-rise and multi-story residential buildings. Understanding the characteristics of aluminum-magnesium-manganese plates can better apply them to various industries.

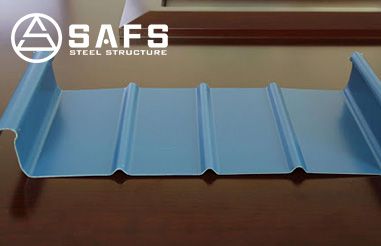

Aluminum-magnesium-manganese plates use high-efficiency, lightweight, thin-walled profiles with light weight, high strength, and small footprint. All components are automated, continuous, and high-precision produced, and product specifications are serialized, finalized, and matched. Structural design, detailed design, computer simulation installation, factory manufacturing, and site installation are carried out simultaneously with a small time difference.

Aluminum-magnesium-manganese plates can be cut, drilled, trimmed, and bent with ordinary machines. When the quantity is large, workers can process and produce semi-finished products, and the production is carried out in an assembly line. The production of aluminum-magnesium-manganese roof panels is related to their support and fixing methods. Usually, a groove with a certain width from the edge is cut and the corners are cut, and then folded into a basin-shaped plate, and then an aluminum square tube is added behind the plate to strengthen it. The surrounding is connected and fixed to the frame by aluminum angle codes (aluminum angle irons). This installation method is relatively strong and has good results. Glue is added between the plate and the reinforced aluminum square tube. This method has been widely used. The groove type usually has several types such as semicircular, 90°U-shaped, 135°U-shaped, etc.

The U-shaped groove can obtain the minimum bending radius. When bending, the plate will be elongated, so the original plate processing length is shorter than the calculated length of the product. This elongated length change is related to the transverse or parallel direction of the aluminum rolling direction, and the bending conditions should be properly considered for testing.

For curved plates, because the composite aluminum-magnesium-manganese plate has excellent processing performance, it can be bent directly on a pressure brake or a rolling mill with three rollers. At the beginning and end of the rolling of the plate, a straight line section of 75~100mm must be left for cutting, which is a requirement of the rolling process. The aluminum square tube as a rear reinforcement of the plate can also be bent directly. This process is important to process the aluminum-magnesium-manganese plate into the shape and size required for construction through cutting, folding, bending, welding, grinding and other processes of the flat plate.