Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Buildings of different regions and different functions have different requirements for the performance of the roof. China metal roof technology development route is from the initial simple waterproof function, and gradually develops to meet the composite functional requirements such as insulation and insulation, noise reduction, sound absorption, and smoke, until the high -quality metal roof project represented by the Olympic venue is completed.

Development of board types and materials

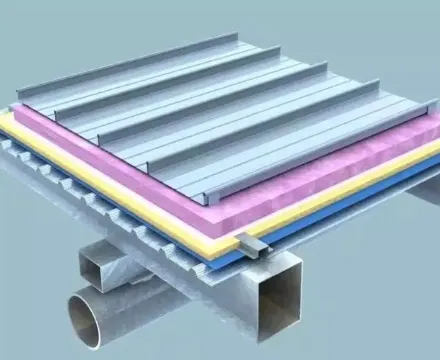

Early metal roof panels, such as W600, V125, etc. Although the wave high is different, the connection method is connected by fasteners. The advantage is that the plate and the bars are connected to the fastener, and it is not easy to loosen under the action of external forces; the disadvantage is that the roof panel is penetrated by fasteners, so it is easy to cause leakage. The emergence of ripple Ⅱ and ripple III plates changed the edge connection method. The connection method of the plate is a hidden 180 ° bite edge connection. There is no fastener penetration on the roof panel. It is a revolutionary change for waterproofing on the board. However, this type of plate type is a non -tight bite that usually uses manual bite, so the construction quality is not high and the wind resistance ability is weak. The 360 ° uplink lock -edge connection plate type represented by the MR24 roof panel of the Bartler Company is bite by a special machine mechanical equipment, and the sliding connection bracket is connected to the pupa system. At the same time, the roof panel can be freely expanded, which effectively solves the system deformation caused by metal material expansion and shrinkage, and ensures the reliability and integrity of the system. It is currently a metal roof panel type worthy of vigorously promoting.

In addition, there is a plate type with a buckle connection method: the side of the voltage steel plate end symmetrically set the bayonet structure edge, the buckle and the bayonet structure side buckle pressure to form an inverted structure, complete the vertical vertical overlap of the voltage steel plate, which also belongs to a hidden connection connection, waterproof performance is better. This connection method depends on the sturdy of the inverted structure, so the rigidity of the color board itself is higher than other structures. When the rigidity of the board is not good, the safety of the connection is very unreliable, and there have been many cases that have been set off by a large number of roofs. Early metal board roof selection was mainly color coating. With the abundance of metal materials, the choice of materials has gradually increased. At present, aluminum alloy plates, stainless steel plates, titanium zinc plates, copper plates, etc.

The use of color coating plate paint has also developed from polyester (PE) surface paint to the current silicon -modified polyester (SMP), high durability polyester (HDP), polytic fluoride (PVDF) and other high weather coatings coexist. Also with functional coating, such as print coating, flower coating, thick membrane coating, self -cleaning coating, antibacterial coating, and anti -static coating plates have also been generally recognized and selected in recent years.

| color coating plate paint | PE | SMP | HDP | PVDF | ||

| functional coating | print coating | flower coating | thick membrane coating | self -cleaning coating | antibacterial coating | anti -static coating |