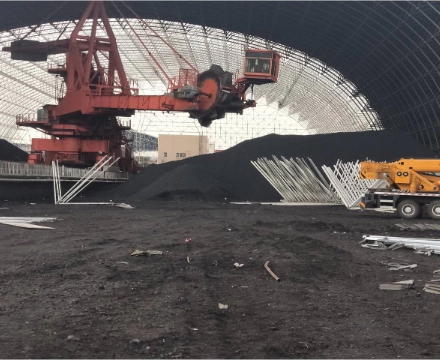

Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

The coal shed space frame serves as the supporting structure for coal stockpiles, undergoing a meticulous production process that includes material selection, welding processes, and surface treatment. Throughout the manufacturing, SAFS Steel Engineering prioritizes material quality, structural design, welding precision, and surface treatment for safety and optimal results.

Material Selection:

Choosing materials aligning with national standards and specifications is crucial. Q235B steel, known for its high strength, toughness, and cost-effectiveness, is commonly used. For higher load-bearing requirements, materials like Q355B steel or others with enhanced strength may be chosen. Corrosion-resistant materials are preferred for humid environments like coal yards.

Structural Design:

Structural design considers factors such as layout, height, and mass of coal stockpiles to accurately calculate the size, shape, and quantity of supporting structures. Key considerations include selecting a foundation structure to meet load-bearing requirements, ensuring structural stability amid lateral pressures and natural elements, and incorporating installation requirements for safety.

Welding Processes:

Welding processes play a vital role in ensuring the quality of the coal shed space frame. Professional operators manage welding processes, ensuring seams are defect-free, free from cracks, bubbles, or slag inclusions. Controlling welding-induced heat deformation and residual stresses maintains the geometric stability of the welded structure.

Surface Treatment:

Surface treatment is essential for extending the lifespan and ensuring safe operation of the coal shed space frame. Different environments require varied surface treatments. Preparing surfaces through methods like acid cleaning, sandblasting, or hot-dip galvanizing is crucial to ensure cleanliness, removing oil, rust, and other contaminants that could affect the effectiveness of surface treatments.

In conclusion, the production process of the coal shed space frame requires consideration of multiple aspects, including material selection, structural design, welding processes, and surface treatment. Diligent execution and careful management of these steps guarantee the quality, safety, and longevity of the coal shed space frame, playing a crucial role in achieving safe and efficient coal yard operations.