Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

As a high -level ultra -static setting space rod system, the space frame structure, due to its good force (theoretically, the rod is only affected by the axis), the rigidity, the overallness and the resistance of the earthquake The uniform sedimentation of seats has a small impact and strong adaptability, and the increasingly perfect calculation theory and the rapid development of computer technology make the analysis and design of any extremely complicated three -dimensional structure. Therefore, the space frame structure is widely used in the field of industrial and civil buildings. However, if the support structure, support structure, and boundary conditions are unreasonable, the space frame structure will have an important impact on the security and economy of the space frame structure.

At present, in many projects, space frame are generally designed by professional steel structure companies based on the boundary constraints of the border in advance, and then use their calculated support from the side to plus the load to the lower support structure. Calculate the space frame frame and the lower support structure, although the displacement of the space frame support from the lower structure can be simulated by elastic constraints. However, the variation of the supporting positions and other supporting support from the lower support structure of the lower support is difficult to estimate the accuracy. In some cases, the structured internal force will be very different from the actual situation. The lower structure may be columns, beams, or other structural forms. Not only is the rigidity limited, but the difference between the stiffness of the specific engineering may be very different. Under such assumptions, the internal force of the rod, the derivative of the support, and the lower structure of the lower structure, and the result of the mechanical model calculated by the mechanical model of the upper and lower structures of the space frame of the space frame support, and these are certainly different. In addition, the separated calculation also splits the coordinated work of the upper and lower structures, so that the cycle and displacement calculation of the upper and lower structures are inaccurate.

Usually the support of the network frame processing can be divided into three ways: peripheral support, point support, and mixed use of dot supportes and surrounding supportes. The surrounding support is to put the peripheral nodes around the rack on the beam or pillar; the point support is to put the space frame support on the independent beam or column at a large distance, and the column is not connected with other structures. When the space frame is put on the beam or column, it can be considered that the vertical stiffness of the beam and the column is very large, and the vertical deformation of the beam and the axial deformation of the column are ignored. The horizontal deformation of the space frame support should consider the joint work of the lower structure. The radial radiation of the surrounding support space frame support should be used as the elastic constraints of the space frame structure of the space frame, and the border conditions of the support support space frame support should be considered in the elastic constraints of the horizontal X and Y directions. The equivalent spring stiffness calculation of the support structure is as follows:

1.Support column support

The equivalent spring stiffness of the horizontal displacement direction is: KC = 3ECIC/H3C

HC: column high; IC: column section inertia.

2.Simplified beam support at both ends

From the length to L, the space frame support is located at the equivalent spring stiffness of the simplified beam of the beam of A as A.

In the formula A: Point from the end of the beam end of the beam; L: beam long; IB: beam section inertia.

3.Rubber cushion support

The rigid springs of the bargaining support from the height of HP are:

Kp = gpap/hp

AP: rubber pad area; HP: rubber pad.

In actual projects, the elastic support of rubber pads is often added to the top of the beam or the top of the column, especially in the large span mesh, through the rubber pad support to meet the deformation requirements of the temperature stress. The stack of elastic rigidity with rubber mats, when K1 and K2 are superimposed, the superposition stiffness k is: 1/k = 1/k1+1/k2; k = 1/(1/k1+1/k2).

The connection area of the structure and the foundation is simplified to supports according to its force characteristics: the activity hinge support (roller support), fixing the hinge support, directional support (sliding support), fixed (end) support support The seat and elastic (spring) support.

The elastic support has a corresponding displacement while providing reaction, and the ratio of the reaction to the displacement remains unchanged, called the stiffness coefficient of the elastic support. Elastic support can provide both mobile constraints and rotation constraints. When the rigidity of the support is similar to the structure, it should be simplified into elastic support. When a part of the structure is affected by the load (such as the stability of the research structure), its adjacent part can be regarded as the elastic support of this part, and the stiffness of the support depends on the rigidity of the adjacent part. When the rigidity of the support is much greater than or far less than the stiffness of this part, the elastic support is converted to the four ideal supports.

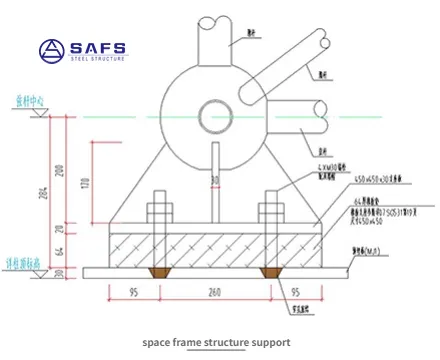

The space frame structure is generally supported on the lower support structure of the column or ring beam. The support node refers to the space frame node located on the support structure. It must be connected to the rods of the meson support office, but also support the entire network frame, and pass the load on the space frame to the lower support structure. Therefore, supporting nodes are links connected to the lower support structure of the meson, and it is also an important part of the entire structure. A reasonable support node must be clear, simple, safe and reliable, and at the same time, it should also be simple and reasonable in structure, simple and convenient production, and good economy.

The supporting nodes of the space frame structure should ensure the security and reliability of the supporting support, so it must have sufficient strength and rigidity. Under the action of vertical loads, support nodes are generally pressured, but in some obliquely placed space frame, local support nodes may withstand the pull force, and sometimes they may also bear the role of horizontal force. When designing, the structure of supporting nodes should adapt to their stress characteristics. At the same time, the structure of the supporting nodes should also meet the calculation assumptions as much as possible to fully reflect the design intent. Since the space frame structure is a high -end super -static rod system, the constraints of supporting nodes have a greater impact on the node displacement and the internal force of the rod; The change of the support of the support of the support sometimes causes the internal force change of the rod. Therefore, the design of the space frame structure support node should be given enough attention.

Whether the design of the space frame structure is safe and economical. The most critical factor is whether the selected support structure, support type and boundary conditions are reasonable. To this end, we can avoid analyzing and designing the upper space frame structure and the lower support system alone as much as possible, especially when the displacement of the space frame support relative to the lower structure is difficult to simulate through the elastic constraint method, the support structure should also be made. The overall modeling and calculation analysis with the upper network shelf makes the calculated results more actual.