Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

1.Rod design

Section design

There are various choices for the cross-section shape of net frame rods. Round steel pipe cross-section force uniformity, torsion performance is good, in the space force advantage is obvious, is a commonly used one. Square steel pipe has good bending resistance and various connection methods. The cross-section size of the bar is determined according to the force. By calculating the internal force generated by the load (including constant load and live load), combined with the strength and stability requirements, the size is selected according to the steel structure design code. For example, compression members should consider the length to slenderness ratio limit to prevent instability.

Material selection

The steel is the main material, like Q235 steel with good toughness and low price, which is suitable for the net frame with small load; Q345 steel with high strength, which is used for large span and heavy load net frame. Material quality level is also very critical to ensure that its chemical composition and mechanical properties meet the requirements.

2.Node design

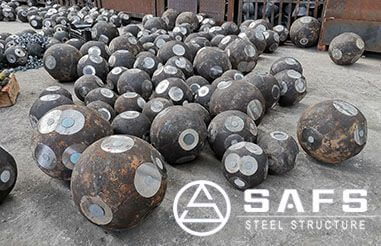

Welded ball node

Welded ball nodes are made of hollow steel balls and rods welded together. Ball diameter should be determined according to the number of connected rods, diameter and angle to ensure that there is enough welding space and good stress performance. The wall thickness of the ball is determined by the node force and ball diameter to prevent local damage. In terms of welding process, we should carefully design the form of bevel, select welding materials and determine the welding sequence to ensure the quality of welding.

Bolt ball node

Bolt ball node contains bolt ball, high strength bolt, sleeve, cone head and seal plate. The diameter of the bolt ball is determined by the number, diameter and angle of the connected bolts to avoid stress concentration. The specification of the high strength bolts is selected according to the node force, and the length should be considered to ensure the appropriate preload by taking into account factors such as the rod and sleeve. Sleeve size should match the bolt and ball, cone head and seal plate size and thickness should be determined according to the rod to ensure reliable connection.

Nodal plate node

Nodal plate node is used for angle steel and other rods net frame. The shape and size of the node plate are designed according to the number of connected rods, angle and force. Its thickness should be able to withstand the force transmitted from the rods to avoid tearing or deformation. Rods and node plate are generally connected by welding, welding length and weld height should be determined according to the internal force and material.

3.Connection method

Welding connection

Welding is commonly used in rod and welding ball node connection. Before welding to clean up the welding part, according to the steel and the requirements of the selection of welding methods, such as manual arc welding or gas shielded welding. Control the parameters during welding to ensure the quality of the weld. Appearance inspection and non-destructive testing after completion, such as checking whether there are biting edges, porosity and other defects, through ultrasonic flaw detection and other checks to ensure compliance with the requirements.

Bolt connection

Bolt connection is used for bolt ball node and part of node plate connection. When installing, ensure that the bolt specification and strength grade are correct. High-strength bolts should be tightened with a torque spanner according to the specified torque, symmetrically from the middle to all sides. Ordinary bolts should be able to penetrate the holes freely to ensure tightness.

Mixed connection of bolting and welding

In some of the net frame using bolt welding hybrid connection, combining the advantages of welding and bolting. For example, in the key nodes first welded to ensure integrity, and then strengthened with bolt connection. Adopt this way to pay attention to the sequence and quality control, to ensure effective function.