Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Colour steel sandwich panel is widely used in the construction field for its many advantages such as beauty, lightweight, heat preservation and insulation. However, there are many kinds of products on the market, and it is crucial to choose correctly.

1.Selection of core material

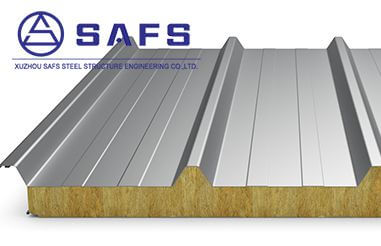

(1)Rock wool core material

Rock wool sandwich panel has excellent fire performance, it is non-combustible material, can effectively prevent the spread of fire. For example, in some of the very high requirements for fire prevention places, such as industrial plants, warehouses, etc., rock wool core material sandwich panels can provide reliable security. At the same time, rock wool also has good thermal insulation properties, its fibrous structure contains a large amount of air, can effectively block the heat transfer, reduce indoor and outdoor heat exchange, thereby reducing building energy consumption.

(2) Polystyrene (EPS) core material

EPS core material of colour steel sandwich panel price is relatively low, and better heat preservation performance. Its closed-cell structure can effectively prevent air convection, so as to achieve the effect of heat insulation. This kind of sandwich panel is more suitable for buildings with requirements for heat preservation and limited budgets, such as some temporary buildings and activity rooms. However, its fire performance is poor, belongs to the flammable material, in the occasion of fire requirements need to be careful when using.

(3) Polyurethane (PU) core material

PU core material sandwich panel thermal insulation performance is more prominent in many core materials. It has a high rate of closed cell, low thermal conductivity, can better maintain the indoor temperature. And PU core material sandwich panel strength is higher, the overall stability of the sandwich panel is good. In some of the insulation and structural strength have high requirements of the building, such as cold storage, high-grade residential roofing can be considered for use. However, its cost is relatively high, and there are some limitations in fire performance, usually B1 level flame retardant materials.

2.Selection of colour steel plate

(1)Thickness and quality of steel plate

Thickness of colour steel plate directly affects the strength and service life of sandwich panel. Generally speaking, the thicker steel plate can withstand greater external force, not easy to deformation. At the same time, pay attention to the quality of the steel plate, high-quality colour steel plate surface coating uniform, bright colour, not easy to fade, and has good corrosion resistance. You can judge the quality of the steel plate by checking its material certificate and test report.

(2) Colour and layout of colour steel plate

As for the colour, it is chosen according to the overall style and usage of the building. If it is used for industrial buildings, it may choose more calm colours such as grey and blue; if it is for commercial buildings or residential houses, the colours can be more rich and diversified. In terms of layout, there are flat panels and corrugated panels. Corrugated panels are stronger and more three-dimensional, and are suitable for roofing; flat panels are easier to install and process, and are commonly used for walls.

3.Other factors

(1) Specification and size of sandwich panels

According to the actual building structure and the use of demand to choose the appropriate specifications and size. Too large or too small sandwich panels may increase the difficulty of installation and material waste. At the same time, it is also necessary to consider the splicing method of the sandwich panel to ensure the sealing and integrality after splicing.

(2) Manufacturers and brands

Choose manufacturers and brands with good reputation and word of mouth. You can learn about the quality of the products and after-sales service by checking the manufacturer’s qualification certificates, user evaluations, and engineering cases.

The correct choice of colour steel sandwich panel requires comprehensive consideration of a number of factors such as core material, colour steel plate, specification size and manufacturer’s brand to ensure that the selected sandwich panel can meet the functional requirements of the building, quality requirements and cost control requirements.