Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

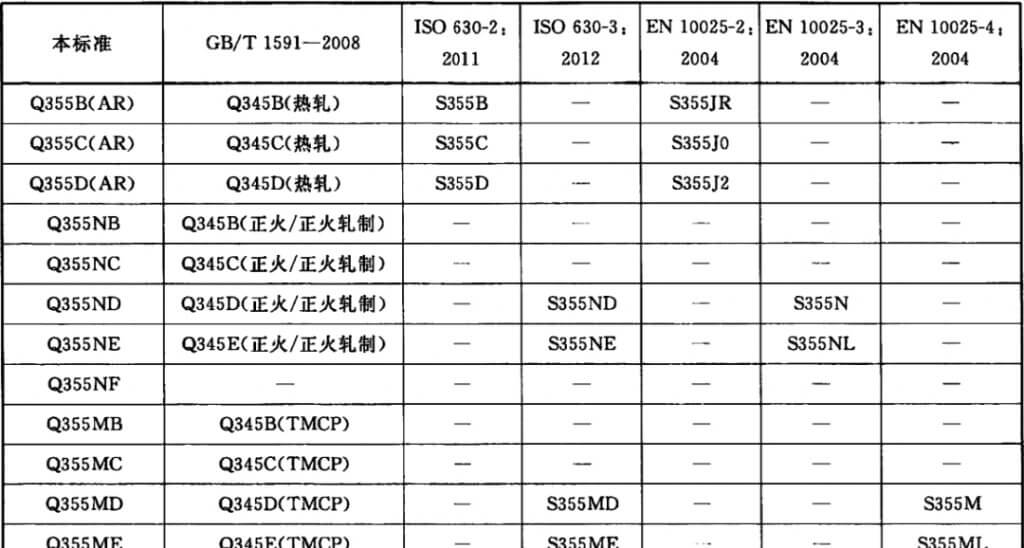

Foreword: Bending is a common metal processing method, and bending cracking defects in steel plate processing are very common. Once cracking occurs, it often leads to disputes between bending plants, traders and steel mills, which delays the schedule and causes economic losses. This article takes the Q355B grade in GB/T 1591 2018 edition as an example to analyze the bending cracking defects. Brief analysis of Q355B grade Q355B grade is included in the 2018 version of the national standard GB/T 1591, which belongs to the low-alloy high-strength structural steel, and is divided into three grades, B, C and D. The 2018 version of the standard replaces the original 2008 version, and the Q345 series is renamed Q355 series, and the grades are divided into finer grades, and the selection of materials has become more complicated.

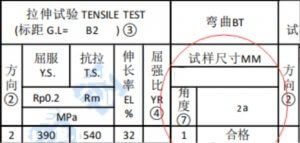

What does “bend pass” mean? Steel materials are standardized products and their properties are clearly described in standards or warranties. For example, bending properties are usually labeled as “Bend Test Pass” in the warranty.

What does “bend pass” mean? Steel materials are standardized products and their properties are clearly described in standards or warranties. For example, bending properties are usually labeled as “Bend Test Pass” in the warranty.

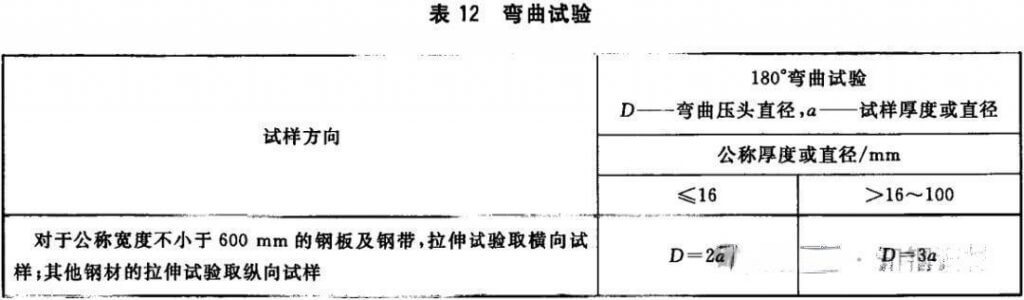

Briefly summarize the requirements of the bending test as follows, the results will not be recognized without the prescribed test.

Bending indenter diameter: twice the thickness of the specimen. Ideas for dealing with bending cracks For our terminal manufacturing enterprises, when encountering bending cracks, the first thing to do is to confirm whether the material is consistent with the standard or the description of the warranty. If the results of the bending test is inconsistent with the warranty or standard, should be communicated with the steel supplier; if the warranty and material testing results are consistent, in line with the standard requirements, the need to design and processing technology to investigate the reasons. In fact, many times bending cracking may not be a material problem, there are cases caused by irrational design or material selection errors. Even sometimes the bonding of materials or surface coating cracks are misjudged as steel bending cracks.

Ideas for dealing with bending cracks For our terminal manufacturing enterprises, when encountering bending cracks, the first thing to do is to confirm whether the material is consistent with the standard or the description of the warranty. If the results of the bending test is inconsistent with the warranty or standard, should be communicated with the steel supplier; if the warranty and material testing results are consistent, in line with the standard requirements, the need to design and processing technology to investigate the reasons. In fact, many times bending cracking may not be a material problem, there are cases caused by irrational design or material selection errors. Even sometimes the bonding of materials or surface coating cracks are misjudged as steel bending cracks.

Conclusion: With the gradual improvement of China’s manufacturing capacity and standardization, the field of industrial circulation on the professional requirements are also higher and higher, which is not only the basis for the survival and development of enterprises, but also to promote the progress of the industry is the key. Correctly interpreting and dealing with “bending and cracking” is also a concrete practice of this concept.