Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

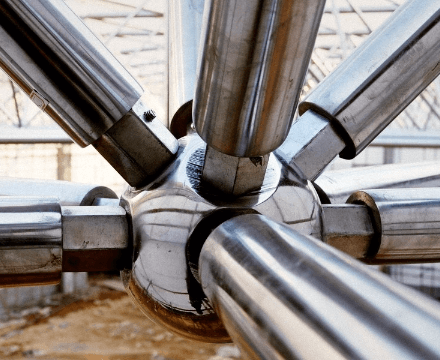

Nowadays, the construction of large, medium -sized steel structure projects has already been presented, and will use the bolt ball space framework. The advantages of the bolt ball connection are relatively significant. They are composed of bearing steel balls, high -strength bolts, and tight bolts. They are also composed of sleeves and cones. The actual application is in the spherical space frame mechanism, and it can have the effect of the connection between the prefabricated components. What should I pay attention to during the production process of high -strength bolts?

(1)The surface of the bolt does not meet the regulations, resulting in the bolt that is not easy to install. Or the level of bolt tightening does not meet the formulation regulations.

Root cause:

Solution:

(2)Bolt wire buckle damage, the screw should not rotate the nut at will, and the installation of the bolt is harmful.

Fundamental reason: Silk buckle is more seriously rusty.

Solution:

The design scheme stipulates that the first or second -level welded seams of the full welding are not selected for the ultrasonic detection; the bearing beam and the column of the floor are not cast; the arc -drawing plate is not selected for welding.

Solution: Before the steel frame structure is welded, check the qualified certificate of the welding wire. The welding strips are used in accordance with the design regulations; welding wires are applied in accordance with the instructions and safety operation regulations, and the surface of the weld should not have cracks and welding scars. One or second -level welds should not have stomachs, welding tumors, and arc pits; welded seams must not have disadvantages such as bite and unpestational thorns; first and second -level welds are carried out in accordance with the requirements. The part should be checked to check the anti -counterfeiting signs of the welder. However, the welded welds cannot be treated by themselves, and the processing processes are set after setting up the processing process. The frequency of welding seams in the same part is not suitable for more than 2 times.