Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

There are many different forms of space frame project design, but according to the difference of its own environment, the selected form may be different, SAFS Steel Structure Engineering Co. basic principles to follow for selection:

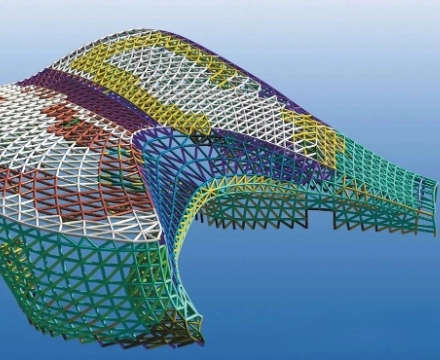

1.Large span space frame project: three-way cross space frame and triangular cone space frame are preferred.

2.Plane intersection truss system: it is preferable to use orthotropic orthotropic form when the plane shape is square or close to square, and it is preferable to use orthotropic diagonal form when the plane shape is rectangular, and it is not recommended to use diagonal diagonal form.

3.The space frame of quadrangular cone system, orthogonal release force uniformity, rigidity is better, orthogonal release pumping to save steel, easy to light, ventilation, diagonal release and star shape is conducive to give full play to the strength of the material.

4.When the plane shape is trilateral, hexagonal or circular, triangular cone system space frame is the choice. Among them, the triangle cone space frame stiffness, hollow triangle cone second, but the material savings, simple construction, honeycomb-shaped stiffness is the worst, the choice should be combined with the peripheral support.

5.The choice of support: peripheral support for large, medium-span space frame, point support flexible arrangement, suitable for large column distance of the plant, warehouse, mixed support for hangar or assembly workshop. The selection of space frame project is not a random choice, according to their own site environment, role and many other factors to consider, so as to ensure that the space frame building to play out their due value.

Space frame material is light weight, easy to install, only manual combination, no need for specialized personnel operating skills. Just follow the construction drawings step by step. It is the ideal choice for industry as well as commerce, municipalities, schools and so on. Wide range of applications, extensive use of light strips, good ventilation, the house can be relocated, the material can be fully recycled, will not cause waste, in line with the sustainable development strategy.

The space frame is made of high-efficiency lightweight thin-walled profiles, with light weight, high strength and small footprint. The components are automated, continuous and high-precision production, and the product specifications are serialized, stereotyped and matched. The size of each part is accurate. Structural design, detailed design, computer simulation installation, factory manufacturing and site installation are synchronized with a small time difference.

Space frame is welcomed by people for its efficient stress performance, novel and beautiful form and fast and convenient construction. In sports stadiums, exhibition centers, cultural facilities, transportation hubs and even industrial plants that require large span and large space, space structures are invariably seen.