Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

Steel space frame is a new type of steel structure. It does not only has the characteristics of large span, wide coverage, and light structure, but also has good stability and stability. It has become a widely used structure. It can be used as the roof of stadiums, theaters, exhibition halls, waiting halls, stadium stands awnings, hangars, two-way large column distance workshops and other buildings.

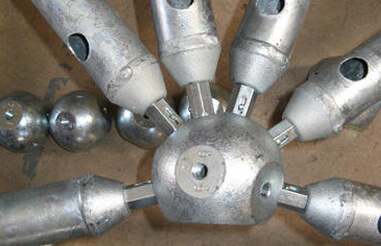

The steel space frame structure is convenient to obtain materials, generally q235 steel and q345 steel are used. There are two types of rod sections: steel pipes and angle steels, and steel pipes have been commonly used. The inspection of the steel space frame can be divided into the bearing capacity of the node, the weld, the size and deviation, the unevenness of the rod, the deflection of the steel space frame and the support of the space frame. The detection methods and allowable deviation values for the deviation of connecting balls, bolt balls, strength bolts and rods shall be carried out in accordance with the “Quality Inspection and Evaluation Standards for “Space frame Structure Engineering“.

The wall thickness of steel space frame steel pipe rods can be tested with a thickness gauge, and the finish layer should be removed before testing. The unevenness of the axis of the rods in the steel space frame can be detected by the method of pulling wires, and the unevenness shall not exceed one thousandth of the length of the rods. The deflection of the steel space frame can be detected by a laser rangefinder or a level. The number of measuring points in each half-span should not be less than 3, and there should be 1 measuring point in the middle of the span, and the distance between the end measuring point and the end support should not be greater than 1m. Also, the measured deflection value should not exceed 1.15 times the corresponding design value. The space frame support can be inspected by observation or with a steel ruler. The support should be stable and firm; the bottom block (or pad) of the support should be free of defects, damage and unevenness.