Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

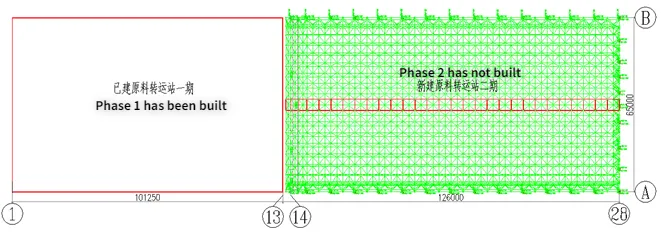

This new project is the second phase of the raw steel structure space frame material transfer station, which is the continuation of the first phase of the project.Its structural form, span, and cladding structure are exactly the same as the first phase of the project. The 1-13 axis is the first phase of the project (built), the 14-28 axis is the second phase of the project (newly built), and the distance between the second phase of the project and the first phase of the project is 1.162 meters. The space frame support is the basis of independent concrete columns. The plane position of the second phase of the project and the first phase of the project below:

Principles of space frame design: The external load of the space frame structure is based on the principle of static equivalent, and the load in the area under the jurisdiction of the node is concentrated on the node. The impact of the rigidity of the node during structural analysis is assumed that the node is hinged, and the rods only bear axial force. The space truss displacement method is adopted when designing the space frame, that is, the three wire displacements of the space frame node are unknown. All rods are hinge rods to withstand axial force, and use the computer for internal force and displacement calculation.

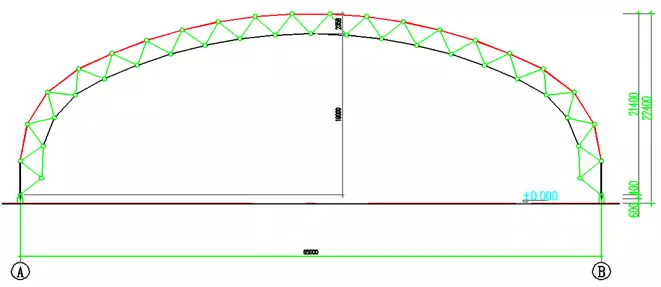

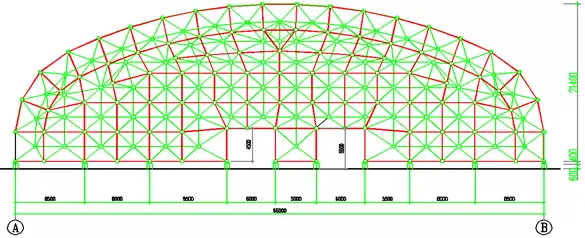

The structure of this project is a shell structure of the bolt ball steel space frame. The space frame form is a square quadrior -tapered double -layer mesh, and the lower strings are supported. The top standard height of the concrete column is 0.6m, and the distance between the length of the space frame (A axis, B axis) is 9m and 6m. The longitudinal length of the space frame is 124.848 meters, the span is 65 meters, and the building area is about 8105 square meters. The cladding system is a metal plate cladding system with local lighting panels.

The steel pipe uses Q235B steel in GFB700. When the thickness of the pipe is less than 7mm, a thin -walled high -frequency welding can be used, and the wall thickness is greater than or equal to 7mm. Seamless steel pipes are used. The bolt ball is 45#steel in high -quality carbon structure steel. The rust -removing level of the space frame is Sa2.5, and the epoxy zinc -rich primer is painted, two epoxy cloud -iron lacquer, and two acrylic polyurethane surface paint. The total thickness of the dry paint film is not less than 125 microns. The fireproof coatings are ultra -thin micro -expanded fireproof coatings, and the refractory grade is secondary (the color of the top paint is determined by the building, and the surface paint can be canceled when there is fireproof coatings). The main roof main purlin is C250X75X20X2.8, and secondary purlin is C160X60X20X2.5. The roof panel is 0.6mm thick 840 sea blue color steel plate, the lighting plate is 1.0mm thick FRP lighting plate (double -folded plate panel wide), and the wall panel is 0.6mm thick 900 sea blue color steel plate. This project space frame span 65 meters and span is super risk.

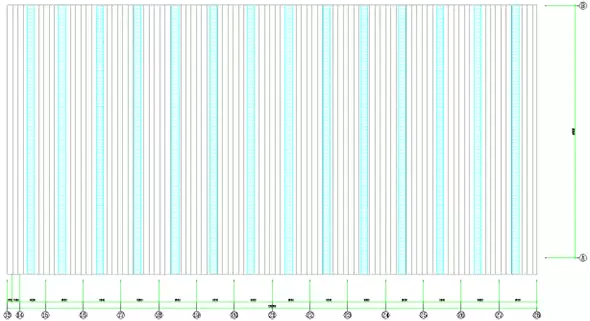

space frame layout

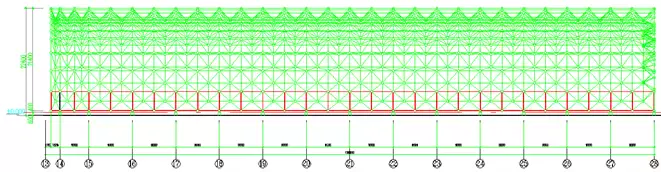

space frame front elevation

14-axis space frame structure elevation

28-axis gable space frame structure elevation

roof panel layout

gable panel layout