Dapeng Town Industrial Park, Tongshan District, Xuzhou City, Jiangsu Province, China

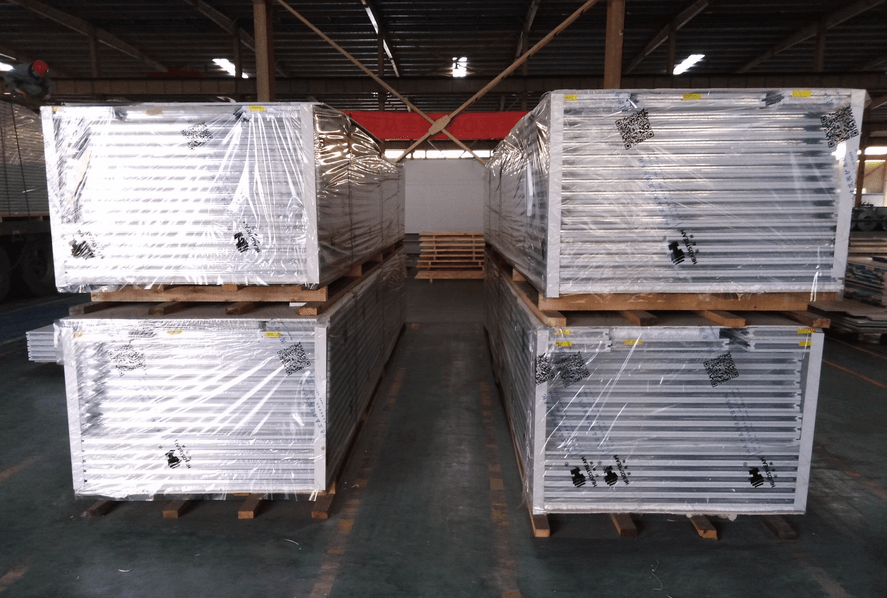

1.1 Storage of color steel plates

Although color steel plates have dual protection of galvanized layer and organic coating on the surface, if they are kept in a humid state for a long time, the water accumulated on the surface (including water produced by condensation in the air) will gradually penetrate through the organic coating, thus causing corrosion of the zinc layer under the organic coating film. Therefore, the following must be noted during storage:

(1) Do not let them get wet, store them indoors, and avoid outdoor stacking.

(2) The indoor environment should be dry and ventilated, free of corrosive gases, and must be avoided from places prone to condensation or large temperature changes. If it is necessary to temporarily store them outdoors, there must be square sleepers underneath, and good ventilation should be ensured. Choose a flat ground, and the top of the sleepers should also be level so that the steel plates are stacked at the same height to prevent warping. The products should be covered with rainproof cloth to protect them from direct exposure to the sun and rain.

(3) If the color steel plates are exposed to rain or condensation occurs, they should be unpacked and dried quickly to remove moisture, and used as soon as possible.

(4) Steel coils should be stored in the state they left the factory as much as possible, and should not be piled up to avoid damaging the coating.

(5) Color coated steel plates should not be placed in places with a lot of sand and dust. If sand and dust accumulate on the steel plate, the coating of the coated steel plate may be damaged. The accumulation of sand and dust will make it difficult for the coating surface to remain dry, which will become the source of corrosion.

(6) Long-term storage should be avoided. When using, the principle of first-in-first-out should be followed to avoid contamination and bruises caused by long-term storage, as well as slight color differences when new and old products are mixed. The storage period should be shortened, especially in coastal and industrial environments.

(7) In order to remove moisture on the surface of the steel plate in the plate package for some reason, the steel plate can be tilted in the warehouse. The appropriate tilt angle is 3.5 degrees.

1.2. Transportation of color steel plates The organic coating on the surface of the color steel plate is easily bruised, so special attention should be paid during transportation.

(1) Products should be transported intact in the state in which they were shipped. The pads should not be removed or the products should not be turned upside down for the convenience of transportation.

(2) When loading and unloading steel plates and steel coils, rubber pads should be used to isolate them from the slings to prevent damage, or special slings should be used.

(3) The carriage for transporting color plates should be cleaned and covered with thick rubber pads or special protective devices should be used to prevent damage to the outer surface of the steel coils. In particular, horizontal steel coils should be placed on uneven truck floor.

(4) When using vertical packaging, the transportation and loading and unloading of color coils should also be kept vertical. When placing vertical steel coils horizontally, a coil turner should be used.

(5) When transporting steel plates and coils, they should be firmly fixed to avoid relative movement between the steel plates and rolling of the steel coils, which may cause scratches.

(6) When taking out the color steel plates one by one, they must not be dragged, otherwise the burrs generated by the cuts and cuts will cause scratches and abrasions on the surface of the steel plates. Therefore, when removing or moving the steel plate, two people are required to hold both ends of the steel plate together and never drag it. And it should be handled with care and not touch other hard objects.

(7) When transportation has to be carried out outdoors due to conditions, a tarpaulin should be covered to protect the product from direct exposure to the sun and rain.

1.3. Development trend of color steel plate

(1) High-quality substrates are used, and the requirements for the surface, plate shape and dimensional accuracy of the substrate are getting higher and higher. Outdoor use includes small zinc flower flat hot-dip galvanized steel coils, zinc flower-free flat hot-dip galvanized steel coils and the emerging zinc alloy hot-dip coils; indoor use includes electro-galvanized steel coils, film-coated cold-rolled plates and aluminum coils.

(2) Improve the pretreatment process and pretreatment solution. The number of equipment is small and the cost is low, which becomes the mainstream process. The stability, corrosion resistance and environmental protection performance of the pretreatment solution are continuously improved.

(3) Focus on the development of new coatings, improve general polyester, polyvinylidene fluoride (PVDF) and plastic sol to obtain super color reproducibility, UV resistance, sulfur dioxide resistance, and improved corrosion resistance; develop functional coatings such as pollution resistance and heat absorption.

(4) The equipment of the unit is more complete. For example, new welding machines, new roller coating machines, improved curing furnaces, and advanced automatic instruments are used.

(5) Since cold embossing is cheaper than hot embossing, and has the characteristics of beauty, three-dimensionality, and high strength, cold embossing production technology has become a development trend.

(6) Focus on product diversification, functionalization, and high-end, such as deep-drawing color-coated plates, “grapefruit peel” color-coated plates, anti-static color-coated plates, pollution-resistant color-coated plates, and high-heat-absorbing color steel plates.