SAFS's assembly process ensures a fast, safe and easy installation at every job site. With SAFS's on-site expert guidance, our structures are installed with locally-sourced labor. All of the structure’s connections are mechanical, so no welding is required.

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Surface Treatment: | Hot Dip Galvanized |

| Grade: | Light Steel | Steel Material: | Q235B/Q355B, 45#, 40Cr |

| Place of Origin: | XuZhou,Jiangsu, China | Design Standard: | AISI,ASTM,BS,DIN,GB,JIS |

| Brand Name: |

SAFS

|

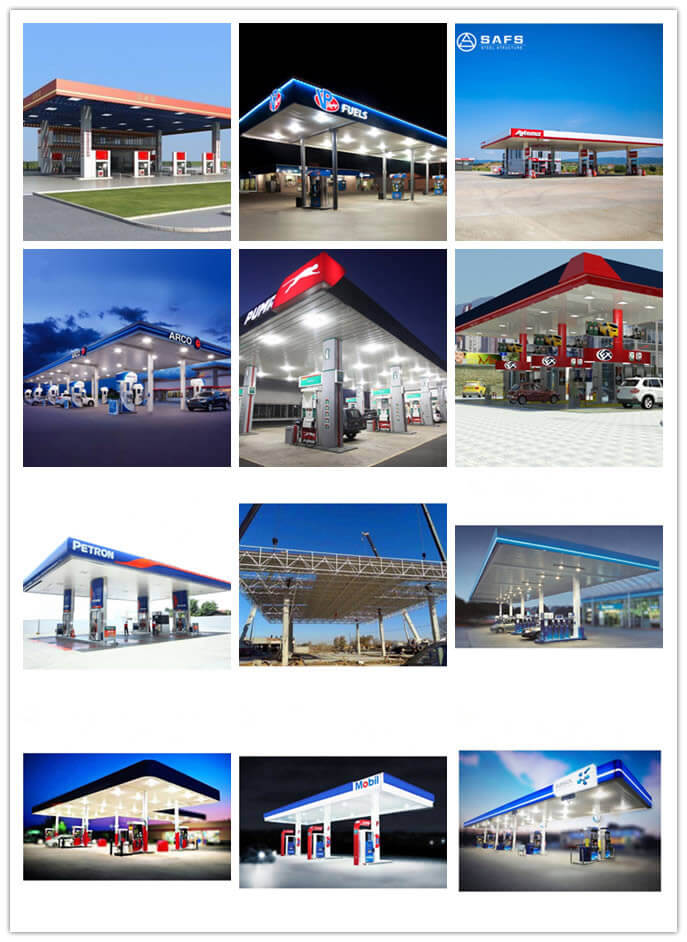

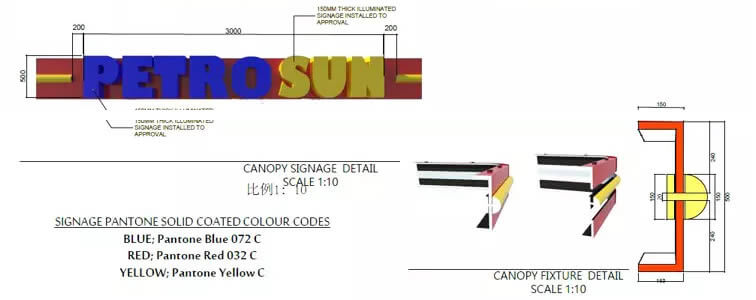

Application Fields: | Gas station Canopy Installation, Petrol Station Canopy Design |

| Model Number: | GS001 | Roof Cover: | Steel Panel / FRP Panel/Customized |

| Type: | Light | Processing: | Bolt Joint Modular Building |

| Application: | Structural Roofing | Life span: | 50 Yeas |

| Tolerance: | ±5% | Size: | Customers’ Requirements |

| Processing Service: | Bolt Joint Modular Building | Certificate: | 2008/CE/BV/ISO/CE |

| Product Name: |

Fuel Station Canopy steel structure gas station design |

Surface: | 3 Layers Painting |

Supply Ability: 2000 Metric Ton/Metric Tons per Month

| Quantity(Square Meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 |

| Est. Time(days) | 25 | 35 | 45 | To be negotiated |

1) Customized design is welcomed.

Welcome to send us your drawings, we will quote you within 24 hours.

A. Customers have the drawings

We can provide you the full service of production, shipment, and installation guide, which is high quality and low cost. Because we own all kinds of technical facilities, complete test instruments, and advanced production processes.

B. No drawings

Our excellent design team will design the gas station for you.

2) We have an excellent design team. According to the requirements of different projects and clients, we will supply different designs and steel products. In order to give you an exact quotation and drawings, please let us know the following information. We will quote for you promptly.

|

No.

|

Item

|

Specification of Project

|

Remarks

|

|

|

1

|

Project Location:

|

_____ Country, Area

|

|

|

|

Project Size:

|

L: ___m W: ___m H: ___m / Dia. ___m

|

|

||

|

Building Shape:

|

Flat / Dome / Arch / Irregular

|

|

||

|

2

|

Wind Load:

|

____kn/m2, ____km/h, ____m/s

|

|

|

|

Snow Load:

|

____kn/m2, ____km/h, ____m/s

|

|

||

|

Seismic Load:

|

____kn/m2

|

|

||

|

Live Load:

|

____kn/m2

|

|

||

|

Dead Load:

|

____kn/m2

|

|

||

|

3

|

Surface Treatment:

|

Painting / Galvanizing / Powder Coating

|

|

|

|

4

|

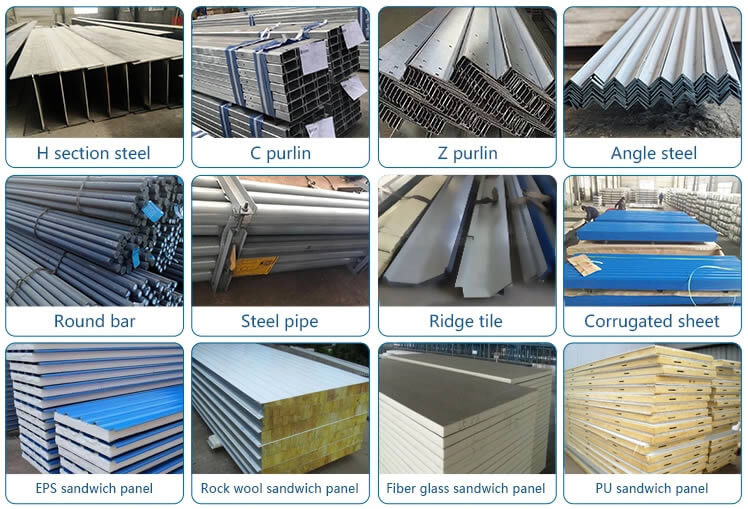

Roof Materials:

|

Color Steel Panel / Sandwich Panel / FRP Daylighting Panels / Glass

|

|

|

|

5

|

Design Standard:

|

GB / ASTM / BS / EN / Other

|

||

Engineering Design Software:

AutoCAD, PKPM, MTS, 3D3S, Tarch,Tekla Structures(X steel)V12.0.etc

|

Item

|

Specification

|

|

|

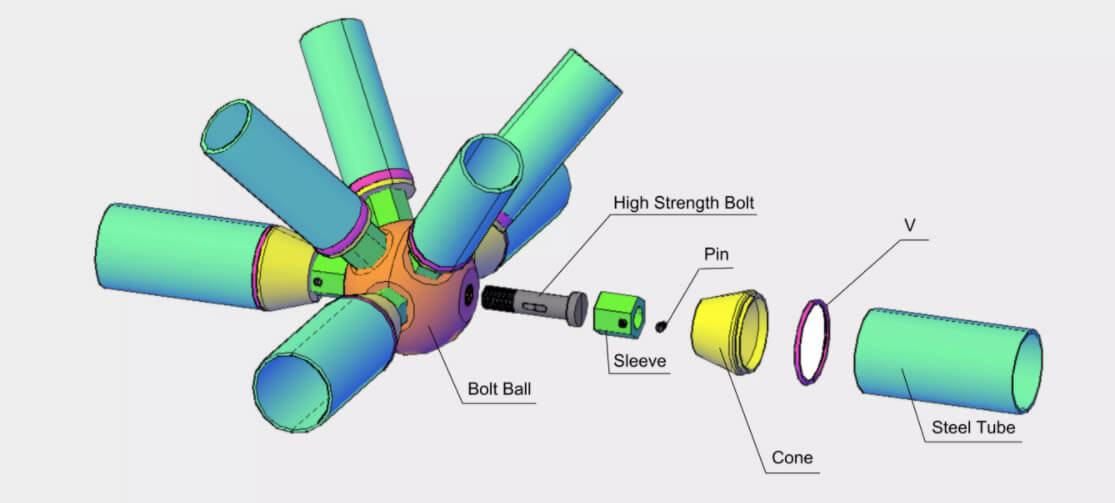

Structural Type

|

Flat Space Frame Structure

|

|

|

Main Frame

|

Steel Pipe

|

Q235B / Q355B Steel

|

|

Bolt Ball

|

45# Steel

|

|

|

Sleeve

|

Q235 & 45#

|

|

|

High Strength Bolt

|

40Cr

|

|

|

Secondary Frame

|

C-Purlin / Z-Purlin

|

Q235B / Q355B, 250g/m2 galvanized layer, no painting on the surface

|

|

Enclosure System

|

Roof Panel /

Ceiling Panel

|

Color Steel Panel / Al-Mg-Mn Panel

(The colors&sizes of all panels can be customized as required.) |

|

Accessory Structure

|

Drainage

|

Galvanized Gutter

|

|

Others

|

Design Standard

|

American Standard / European Standard / Chinese Standard

|

|

Design Lifetime

|

Above 50 years

|

|

|

Fabrication

|

ISO Quality Control

|

|

|

Surface Treatment

|

Blast Cleaning Sa2.5 level, painting or galvanizing

(The thickness can be customized as required.) |

|

|

Packing

|

Metal Frame for Large Components, Wooden Case, or Metal Case for Small Components.

Or Bundling |

|

|

Installation

|

Installation Guide

|

|