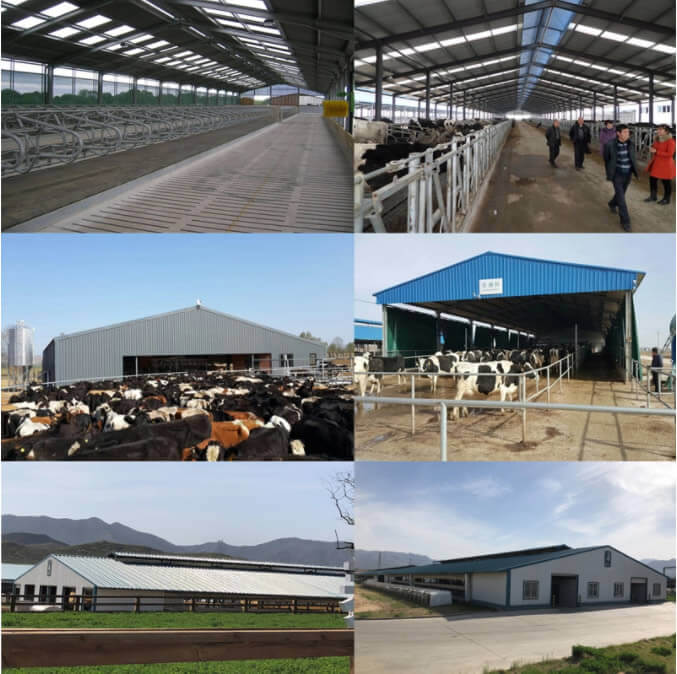

1. Closed Type ( with roof and wall panel cladding)

2. Open Type (no wall or wire mesh&curtain for the wall)

3. It can be with different structure types, one is the portal frame structure and another is the roof truss structure.

As long as you can have your own thoughts, we will help you to realize them.

Our Poultry farm can be built with different methods:

1. Closed Type ( with roof and wall panel cladding)

2. Open Type (no wall or wire mesh&curtain for the wall)

3. It can be with different structure types, one is the portal frame structure and another is the roof truss structure.

As long as you can have your own thoughts, we will help you to realize them.

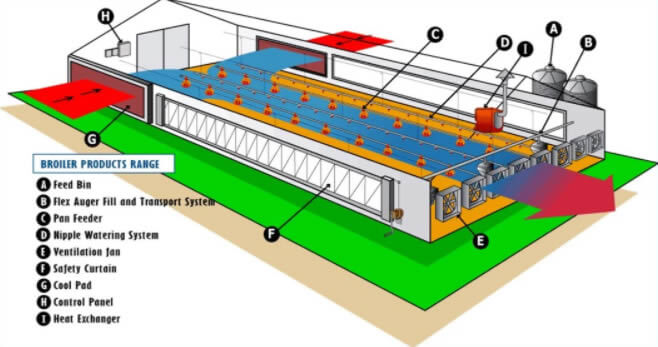

The poultry farm is mainly used for broiler and layer chicken, you can choose a free-range or cage system with automatic equipment to breed.

We can introduce our partner (the equipment supplier) to you, then we work together to provide a more workable project for you.

Inside Breed System

1. Automatic pan feeding system

2. Nipple drinking system

3. Ventilation system

4. Cooling pad system

5. Heating system

6. Environment control system

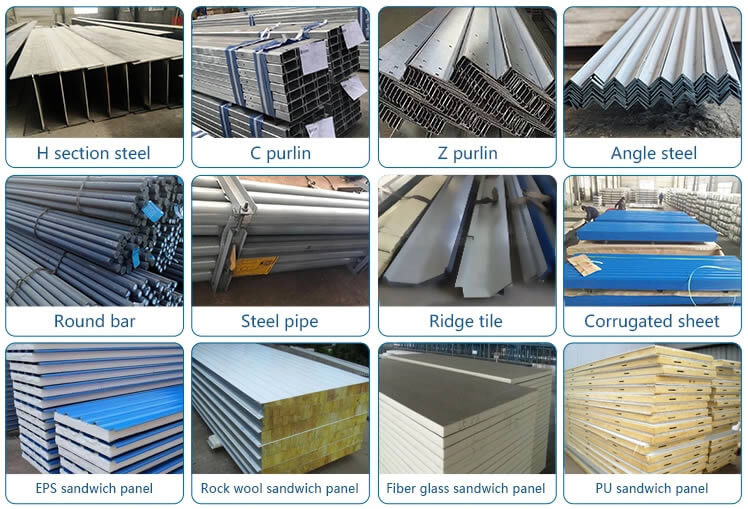

| Standard: | AISI, ASTM, bs, DIN, GB, JIS | Grade: | Q235B/Q355B Carbon Steel |

| Place of Origin: | Jiangsu, China | Brand Name: | SAFS |

| Model Number: | Portal Steel Structure Breeding Shed | Type: | Light, Light Steel Structure Frame |

| Application: |

Gym, Stadium/Sports Hall,/Gymnasium/Hangar/ Warehouse/Workshop/Sheds/Office Building |

Tolerance: | ±1% |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching | Product name: | Portal Steel Structure Breeding Shed |

| Main structure: | Section Column | Purlin: | C/Z Galvanized Steel(Q235) |

| Surface treatment: | Painting or Galvanizing | Wall&Roof panel: | Steel Sheet or Sandwich Panel |

| Structure type: | Light Portal Frame Structure | Certificate: | ISO9001:2008 ISO14001:2004 |

| Life span: | Up to 50 Years | Drawing design: | SAP2000/AutoCAD /PKPM /3D3S/TEKLA |

Supply Ability: 100000 Square Meter/Square Meters per Month steel structure Breeding Shed

| Quantity(Square Meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 |

| Est. Time(days) | 25 | 35 | 45 | To be negotiated |

1) Customized design is welcomed.

Welcome to send us your drawings, we will quote you within 1 day.

A. Customers have the drawings

We can provide you the full service of production, shipment, and installation guide, which is high quality and low cost. Because we

own all kinds of technical facilities, complete test instruments, and advanced production processes.

B. No drawings

Our excellent design team will design the light steel structure warehouse/workshop/poultry house/hall for you.

2) We have an excellent design team. According to the requirements of different projects and clients, we will supply different designs and steel products. In order to give you an exact quotation and drawings, please let us know the following information. We will quote for you promptly.

Basic design requirements of steel structure Breeding Shed(chicken house, duck house, pig shed, cowshed, etc.)

| Basic Design Requirements | ||

| 1.Project location | 5.Length (sidewall,m) | 9.Window quantity, size |

| 2.Snow load | 6.Width (end wall, m) | 10.Door quantity, size |

| 3.Wind load | 7.Wall Height (eave, m) |

11.Brickwall needed or not. If yes, 1.2m high or 1.5m high |

| 4.Seismic magnitude | 8.Middle column allowed or not |

12.Crane needed or not |

|

13.Thermal insulation. If yes, EPS, fiberglass wool, Rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former. |

||

Engineering Design Software:

AutoCAD,PKPM,MTS,3D3S,Tarch,Tekla Structures(X steel)V12.0.etc

| Items | Specifications | |

| Main Steel Frame | Column | Q235B, Q355B Welded H Section Steel |

| Beam | Q235B, Q355B Welded H Section Steel | |

| Secondary Frame | Purlin | Q235B C and Z Purlin |

| Knee Brace | Q235B Angle Steel | |

| Tie Rod | Q235B Circular Steel Pipe | |

| Brace | Q235B Round Bar | |

| Vertical & Horizontal support | Q235B Angle Steel, Round Bar, or Steel Pipe | |

| Maintenance System | Roof Panel |

EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

| Wall Panel |

EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

|

| Accessories | Window | Aluminum Window, Plastic Steel Window |

| Door | Aluminum Door, Rolling Metal Door | |

| Rainspout | PVC | |

| Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts | |

| Ventilation System | Natural Ventilator, Ventilation Shutters | |

| Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-Resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Temperature | Suitable temperature -50°C~+50°C | |

| Certification | CE, SGS,ISO9001:2008,ISO14001:2004 | |

| Finishing Options | A vast array of colors and textures available | |

All the components will be prefabricated in the factory before transported to the construction site. The installation process is quick and easy.

It will significantly shorten the construction period of your buildings, saving a great deal of time and money.

The steel structure has a lightweight but high strength, which is also easy to maintain. It can be utilized for over 50 years.

The prefab steel workshop can be isolated against outdoor environments as well as avoid any leak like water seepage. It also has excellent fire resistance and corrosion resistance.

It is easy to move and relocate steel structure, which can also be recycled without pollution.

The steel structure fabrication workshop is capable of withstanding the attack of strong winds and heavy snow. It also has an excellent seismic performance.