The steel structure gymnasium gathers more application functions and brings more vitality to the urban economy. It is constructed with bolted ball space frame connection, which greatly shortens the construction time and cost. Because of its beautiful appearance, it has gradually become a local landmark.

Construction of the gymnasium

1.The safety requirements are extremely high. As a public building, the safest structure must be considered. Must have the ability to resist natural disasters.

2.Beautiful appearance, many stadiums have become local landmarks after they are built.

3.The span is large, but the purpose of use requires no or fewer columns as much as possible. If there are too many overhangs, the safety of the structure is unfavorable.

4.Strong durability, long service life, and structure as little maintenance as possible.

5.Short construction period and simple installation.

Scope of application

1.Basketball court space frame

2.Badminton court space frame

3.Volleyball court space frame

4.Indoor football field space frame

5.Bullring space frame

6.Swimming pool space frame

7.Arena space frame

9.University gymnasium space frame

10.Exhibition hall space frame

Solution

The roof of the stadium requires a large span and a large space. At the same time, the structure is also required to have good wind resistance, snow resistance, and seismic performance, as well as higher safety performance requirements. The space frame structure meets this feature. Therefore, in the stadium we built The space frame structure accounts for more than 80% of the total number.

1.The structure has multiple times of statically indeterminate characteristics, good internal force automatic distribution and adjustment, and it is currently the safest type of all structural systems. The performance of wind, snow, and earthquake resistance is very good.

2.Various shapes can be realized, beautiful and generous

3.The structure can achieve a large span, and professional software can be used to optimize and safely arrange the column points

4.It can be designed according to the safety of 50 and 100 years of use. Once completed, reliable corrosion protection can minimize maintenance workload.

5.For the structure, only bolts are needed on-site to shorten the construction period as much as possible, and the installation quality is high, and the safety hazards are minimized.

6.The overall cost is low, cost-effective, and the total cost and the total cost of the trial period is very well controlled.

7.In China, the structure is used in schools and public buildings. After an earthquake or natural disaster occurs, it is used to house victims. After the design safety level is reached, the structure will not be damaged by earthquakes or strong winds. It is strong and safe.

For large-area membrane roofs, on-site welded pipe trusses are recommended.

Process Description

1.Design process:

(1)The Stadium Roof adopts the space frame structure. It is recommended that the structural importance coefficient must be amplified according to the use requirements and the natural disasters that may be encountered in the area. Even if there is no requirement, it should be enlarged to at least 1.15 to 1.2 (standard requirements, but also Other considerations).

(2)Consider more possible combinations in load combinations, and load combinations with less impact should also be considered;

(3)Pay attention to the loads such as hanging lamps on the lower string, overhauling horse tracks, and ceilings, and also taking into account the concentrated hanging loads that may appear in possible places in the future.

(4)The calculation strength of the components should be considered more conservative and safer, and any possible hidden dangers must be considered and enlarged. It cannot be ignored because of the uncertainty of the economy or safety risks.

(5)Anti-wind, anti-snow, anti-seismic, and other extreme weather should be pre-judged. Ensure the safety of the Stadium Roof space frame from the design source!

2.Production process:

All-round factory quality control of materials, processing, and welding must be carried out to ensure the quality of the components. After the material self-inspection, it must be re-inspected by a third party for processing. The processed materials need to be tested The indoor destructive test is conducted to ensure that the quality of the components is excellent before leaving the factory.

3.Installation process:

The quality of installation is related to the safety of later use. For large stadiums, we will recommend the installation by skilled Chinese workers. During the installation, skilled workers must be directed by experienced on-site technicians to install. It is not recommended that local workers undertake the main task of installation, except for non-important parts such as roofing. After installation, we will check to eliminate possible hidden dangers and ensure safety before use.

| Standard: | AISI, ASTM, BS, DIN, GB, JIS | Surface Treatment: | Hot Dip Galvanized |

| Grade: | Light Steel | Steel Material: | Q235B/Q355B, 45#, 40Cr |

| Place of Origin: | Jiangsu, China | Design Standard: | AISI,ASTM,BS,DIN,GB,JIS |

| Brand Name: |

SAFS

|

Application Fields: | Indoor Stadium |

| Model Number: | CS051 | Roof Cover: | Steel Panel / FRP Panel/Customized |

| Type: | Light | Processing: | Bending, Welding, Decoiling, Cutting, Punching |

| Application: | Structural Roofing | Life span: | 50 Yeas |

| Tolerance: | ±5% | Size: | Customers’ Requirements |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching | Certificate: | SGS ISO CE etc. |

| Product Name: |

Portal Steel Structure Indoor Stadium |

Supply Ability: 2030 Metric Ton/Metric Tons per Month

| Quantity(Square Meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 |

| Est. Time(days) | 22 | 31 | 43 | To be negotiated |

1) Customized design is welcomed.

Welcome to send us your drawings, we will quote you within 1 day.

A. Customers have the drawings

We can provide you the full service of production, shipment, and installation guide, which is high quality and low cost. Because we

own all kinds of technical facilities, complete test instruments, and advanced production processes.

B. No drawings

Our excellent design team will design the light steel structure Gymnasium/warehouse/workshop/poultry house/hall dome coal storage system for you.

2) We have an excellent design team. According to the requirements of different projects and clients, we will supply different designs and steel products. In order to give you an exact quotation and drawings, please let us know the following information. We will quote for you promptly.

Basic design requirements of steel structure indoor Gymnasium

| Basic Design Requirements | ||

| 1.Project location | 5.Length (sidewall,m) | 9.Window quantity, size |

| 2.Snow load | 6.Width (end wall, m) | 10.Door quantity, size |

| 3.Wind load | 7.Wall Height (eave, m) |

11.Brickwall needed or not. If yes, 1.2m high or 1.5m high |

| 4.Seismic magnitude | 8.Middle column allowed or not |

12.Crane needed or not |

|

13.Thermal insulation. If yes, EPS, fiberglass wool, Rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former. |

||

Engineering Design Software:

AutoCAD,PKPM,MTS,3D3S,Tarch,Tekla Structures(Xsteel)V12.0.etc

Marshall-stadium-roof-structure

| Items | Specifications | |

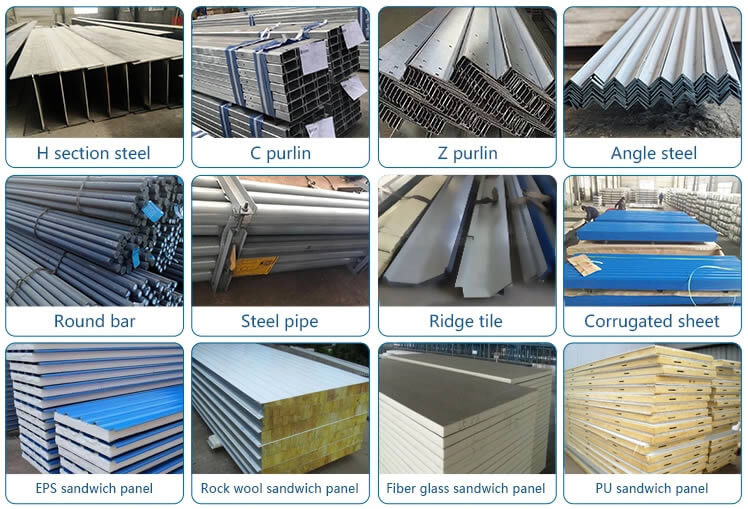

| Main Steel Frame | Column | Q235B, Q355B Welded H Section Steel |

| Beam | Q235B, Q355B Welded H Section Steel | |

| Secondary Frame | Purlin | Q235B C and Z Purlin |

| Knee Brace | Q235B Angle Steel | |

| Tie Rod | Q235B Circular Steel Pipe | |

| Brace | Q235B Round Bar | |

| Vertical & Horizontal support | Q235B Angle Steel, Round Bar, or Steel Pipe | |

| Maintenance System | Roof Panel |

EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

| Wall Panel |

EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

|

| Accessories | Window | Aluminum Window, Plastic Steel Window |

| Door | Aluminum Door, Rolling Metal Door | |

| Rainspout | PVC | |

| Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts | |

| Ventilation System | Natural Ventilator, Ventilation Shutters | |

| Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-Resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Temperature | Suitable temperature -50°C~+50°C | |

| Certification | CE, SGS,ISO9001:2008,ISO14001:2004 | |

| Finishing Options | Vast array of colors and textures available | |